Makes everything simple.

cyber® iTAS® system 2 – the drive system for AGVs

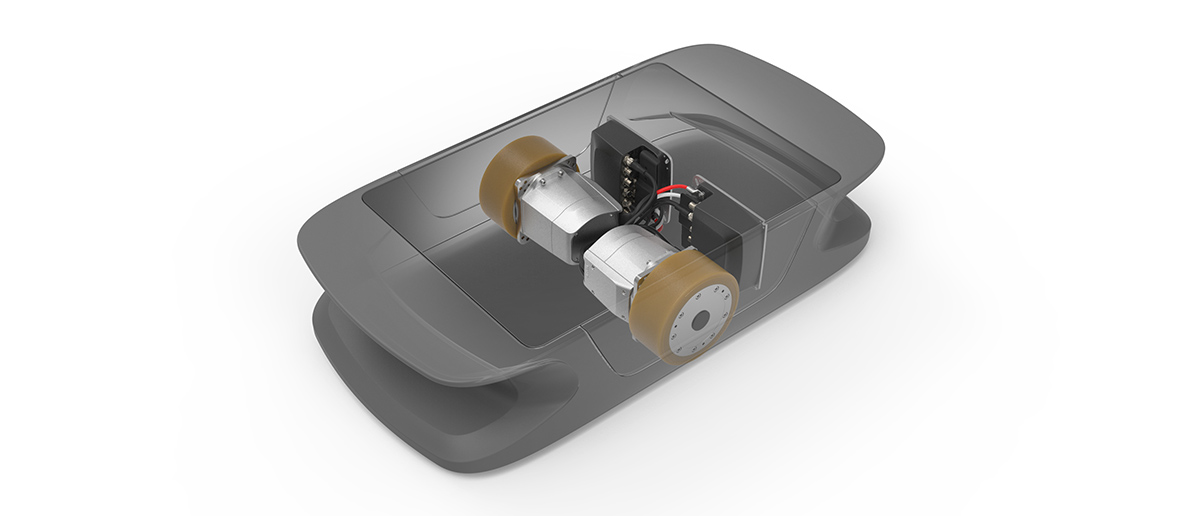

The cyber® iTAS® system 2 is the next generation of our compact servo drive system for automated guided vehicles (AGVs), autonomous mobile robots (AMRs) and other mobile platforms with vehicle masses between 1 t and 3 t. It makes it much, much simpler for vehicle manufacturers to realize features in the areas of safety, performance, connectivity, flat design and service.

All bases covered.

The cyber® iTAS® system 2 consists of a safety certified servo drive from the cyber® simco® drive 2 series as well as a compact and heavy load wheel actuator in the form of the cyber® TAS actuator 2. The use of two systems per vehicle creates a differential drive that generates a precise steering function via different speeds or directions of rotation for each wheel. In addition, the smart design of the safety architecture boasts many innovative safety functions.

This makes the cyber® iTAS® system 2 the ideal choice for AGVs and AMRs etc. – in both classic and collaborative working environments.

Find out more about the cyber® iTAS® system 2 product portfolio

A perfect team makes everything possible.

The compact cyber® simco® drive 2 servo drive with a maximum current of 200 A is insensitive to dust and moisture in protection class IP65. This allows it to be placed in the immediate vicinity of the wheel actuator without much wiring.

Find out more about the cyber® simco® drive 2 product portfolio

The cyber® TAS actuator 2 in our drive system with a payload of 750 kg is a miracle in miniature: The wheel actuator measures just 180 mm high and 230 mm long. Therefore, simply perfect for very flat and narrow vehicles.

Simpler than ever.

Download

Contact us

Is there anything you'd like to know about the iTAS® servo drive system?

Do you require individual advice? If so, please contact us directly. We look forward to hearing from you!